Fine points regarding the alignment of a Blum cabinet slide: What makes the screw holes not parallel using the cabinet bottom? July 29, 2011

Fine points regarding the alignment of a Blum cabinet slide: What makes the screw holes not parallel using the cabinet bottom? July 29, 2011

Concern

I'm getting ready to produce a task with 70 compartments. Oahu is the very first one We have carried out in quite a long time with Tandem slides. We're carrying it out in this manner because we have been matching a project we did for these people a decade ago.

I moved away from undermount slides since they required a lot of tune-up after being installed inside case. The vast majority of our work is flush inset and I ended up being concerned with the longevity of any alterations we made after fat and characteristics had been added to the equation.

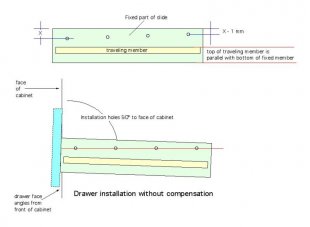

If you look closely during the an element of the fall which mounts into the pantry box, you will notice that the installation holes aren't parallel with all the slip it self. In reality, the slip was designed to drop 1 mm behind. This drop results in a drawer face that mathematically steps away at the end, for this reason the need for ratchet modification at back. What sort of slip is designed, but really creates a drawer package installation where the bottom of drawer package is parallel with bottom of overall slip system. If, during cabinet slide installation, you index your fall parallel from bottom of the pantry (as opposed to a screw gap pattern perpendicular to front of closet), you do not have this cabinet face shingling result. Most of the factors agree with each other in a 90 commitment.

My concern is because of the Blumotion part. Blum engineered this tipping activity for grounds. Had been this to aid the spring/piston to close the drawer? Are there any durability problems related to not including this tipping activity during slip installation?

Forum Resposnes

(Cabinetmaking Forum)

From factor K:

Interesting... Im today interesting. I usually install my slides parallel because of the porches.

From contributor R:

There is certainly somewhat lever regarding the straight back of the slides next to the hook as you are able to rotate and raise the straight back of cabinet boxes to plumb the fronts.

From original questioner:

The lever at straight back part is just advantageous in case the slip is canted reduced at backside. If you index fall installation parallel to cabinet deck, there's no gravity taking care of part regarding the cabinet fall. The question is whether or otherwise not this gravity is an assist into the Blumotion an element of the slip.

From contributor R:

Yes, the slides should slope toward back in order that gravity can shut all of them. The lever into the back allows you to make up for the pitch and plumb your fronts.

If you like much better modification features, make use of the Accuride Eclipse slides.

From contributor D:

Interesting observation. It appears in my opinion there clearly was a matching quantity of play/rock inside sliding members. It might be determined by the slide, nevertheless the rocking/pivot point/bearings tend to be behind the midpoint associated with the cabinet as well as the front side of cabinet is heavier as compared to straight back. If mounting holes had been parallel, the drawer field would remain low in leading.

From contributor L:

I have tried personally Blum combination for many years and also...

RELATED VIDEO